How Laser Precision Engineers Aid in the Production of Quality Parts

July 12, 2017

Most costly errors and waste in the manufacturing process come from miscommunication. Blueprints or sets of instructions that are not clear, precise and readable can spell disaster when turning out parts with tolerances tighter than the thickness of a human hair. The risk of costly mistakes by human error rises exponentially with the number of people involved. At Laser Precision, the front line defense against ambiguity in our manufacturing process is our Engineering Department.

Most costly errors and waste in the manufacturing process come from miscommunication. Blueprints or sets of instructions that are not clear, precise and readable can spell disaster when turning out parts with tolerances tighter than the thickness of a human hair. The risk of costly mistakes by human error rises exponentially with the number of people involved. At Laser Precision, the front line defense against ambiguity in our manufacturing process is our Engineering Department.

What to Build

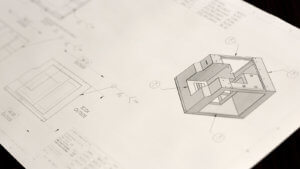

Once an order has been accepted, we take our customer’s part specifications and build a 3D computer model before we ever begin production in the facility. This allows us to confirm manufacturability of the part along with the process all in a virtual setting. Notes are added on any issues that might occur and how to overcome them when working with actual materials. Advancements in software have allowed us to create virtual prototypes that are so accurate that actual working prototypes are rarely required, which is a huge cost savings in time and material.

How to Make It

The next step is for the engineer to create detailed prints based on the 3D model that will ultimately be transmitted out to the floor during the manufacturing process. These include the dimensions of the part along with any tolerances that need to be noted. It may also contain special items such as masking notes for painting, etc. All of this information is contained on a BOM (bill of materials) and router which describes in depth every operation that needs to be completed in order to manufacture the part. Any errors or issues that have arisen on previous runs from the past are documented as a “heads up” so they can be avoided. Every effort is made to make the documents concise, clear and readable. Engineers and operators work together to determine the best way to display notations on the prints, down to placement on the page and even font size. “Exploded views” are added when necessary for clarity.

Mapping a Minefield

The prints and routers now become living documents. This is where our engineer and operators work in harmony to defuse any potential issues. Often our operators are working without end user knowledge and how a finished part we manufacture will integrate within a larger assembly. There are often critical dimensions or tolerances that must be met for other pieces to fit appropriately, which are flagged by engineering for operators to recognize right away. An example of this might be laser cut parts that require forming but are coming out of a nested sheet. Often times, they can look identical on a laser cut sheet. The special notations provided by engineering allow our operators to easily identify a part and know how to form it without missing a step.

These issues (along with many others) are why our Engineering Department is so careful in building clear and concise instructions on the front end before any manufacturing takes place on the production floor. We’ve found adding simple notations and providing clear instructions makes all the difference in ensuring a part is made to print every single time.

Into the Shop

Along with the electronic files, paper prints, control plans and routers travel with the jobs so everyone stays on the same page on the tracking and progress of each job. Scheduling software and supervisors manage the flow and operators at each stage and clock the jobs in and out so each operator knows what parts are coming and when they are due.

Customer Liaison

Sometimes an operator will spot a problem with a particular tolerance, an odd bend or experience difficulty working a large part. Our engineering team coordinates with customers on a concept and functionality to take a step back and see if the manufacturing can be done differently or more efficiently. For example, many parts are designed to be made in two pieces and then welded together. A more cost effective alternative is to laser cut and form the part out of one piece, and generally it can function just as well if not better than the original two piece design. While this isn’t always applicable, it serves as an example of how we engineer for cost reduction and manufacturability.

Continuous Support

It takes an incredible amount of work and due diligence on the front end to design a repeatable process that enables our operators to produce parts that match our customers’ expectations consistently and reliably. Our Engineering Department coordinates this effort and executes the working documents with such precision that with every new part, we can proceed with confidence that the manufacturing process will go smoothly. Ultimately, this reduces errors, time, and the cost of manufacturing.

If you would like to learn more about our metalworking capabilities, please contact us.