5S Methodology: Adding Structure to Continuous Improvement

April 19, 2019

At Laser Precision, continuous improvement has always been a way of life. Sometimes it occurs organically. Other times we take a more scientific approach, such as when we make a decision to purchase new equipment (See Capital Expenditures Add Value).Another tactic is to research what has worked for others and see if it can be adapted to our own operations. This is the case with 5S Methodology, a workplace organization method that we are currently implementing in our shop.

the orgins of 5s methodology

While some Western companies discovered and applied some of the underlying concepts of 5S on their own, the practice was formalized in Japan and became popular after being published in English.It has been acknowledged as being one of the techniques that made Just-in-Time manufacturing possible. A key concept of the 5S Methodology is to provide employees with acknowledgement that every job is essential to the production process and the quality of the end product.

The five elements of 5s

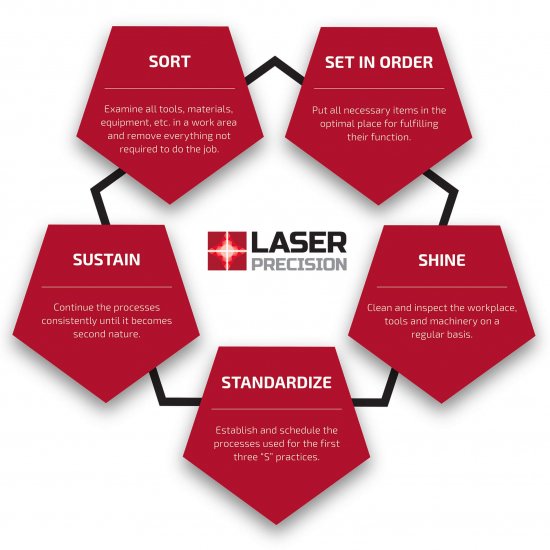

The foundation of 5S comes from the Japanese words Seiri, Seiton, Seiso, Seiketsu and Shitsuke. These are generally translated into English as follows:

Sort: Examine all tools, materials, equipment, etc. in a work area and remove everything not required to do the job.

Set in Order: Put all necessary items in the optimal place for fulfilling their function.

Shine: Clean and inspect the workplace, tools and machinery on a regular basis.

Standardize: Establish and schedule the processes used for the first three “S” practices.

Sustain: Continue the processes consistently until it becomes second nature.

a solid foundation

As you might expect from reading previous articles in our blog, Laser Precision has discovered and adopted some concepts from 5S on our own, based on insights from our staff. These ideas were implemented because they made good sense and add value for our customers.

For example, we’ve given a lot of thought to the way we’ve placed our equipment on the floor for the best process flow. From our lasers, to large and small press brakes, to the CNC milling section, to manual grinding right down to the logistics of the dock. The flow is very clean and highly functional.This careful planning has given us a head start in adopting 5S methodology in the shop.

5s methodology at laser precision

Building on this base, our continuous improvement program moved forward, but on a piecemeal basis. Frankly, our business was growing at such a rapid pace, the time required to put a formal program in place was hard to find.

We realized the only way for improvement to grow organically and continually from the ground up was to embed it into the company culture. For that reason, the creation of a mindful 5S structure became a priority for the current year.

To bring this about, we have developed an internal 5S committee under our Logistics Manager, Doug Comerford, and Production Manager, Jason Ming. This group meets monthly and is charged with the task of launching a formal program and organizing it throughout the company.

the goals of 5s methodology

Our 5S program is designed to set up a discipline that encourages each employee to develop a tactical and innovative mindset. Many already have this, but we need a more structured approach to achieve company-wide participation and ingrain the concept into the company culture.

In addition, the formal 5S structure will speed up the process with a formal pipeline that will enable innovative ideas to rapidly reach decision-makers. Previously, a wonderful suggestion for process improvement might not even come to light unless a chance meeting took place between the right people at the right time.

“Our professionals on the floor have some great ideas, but they are extremely busy as well, and we all get bogged down in day to day operations,” said Comerford. “We would be doing a disservice to ourselves and our customers if we didn’t move the culture forward and evaluate, measure, monitor and integrate these suggestions into the business much faster.”

“You might say the new 5S program is our way of improving our continuous improvement program. It’s just another example of our commitment to constantly examine every aspect of our operations to add value for our customers.”