Data That Doesn’t Lead To Action Is Useless! (Part 1 of 2)

October 09, 2017

Laser Precision is an award-winning, full service sheet metal and plate fabricator. So why do we think of ourselves as a data processing company? The answer to that question is also the key to understanding how we became a thought leader for innovation in the fabrication industry and grew from an organization that had only 250 parts in our library to now having over 6,000 parts for some of the largest OEM’s in the world.

Laser Precision is an award-winning, full service sheet metal and plate fabricator. So why do we think of ourselves as a data processing company? The answer to that question is also the key to understanding how we became a thought leader for innovation in the fabrication industry and grew from an organization that had only 250 parts in our library to now having over 6,000 parts for some of the largest OEM’s in the world.

In 2005, we were bogged down and had the same production problems as everyone else in the industry. We just couldn’t consistently deliver parts on time. We purposefully set out to create a new business model that would increase the quality and speed of each operation in our facility. We knew that for the company to grow, we had to find a better way to create, deliver, and capture value.

Lazy Data

It was quickly determined that collecting data was not the problem. Long before Industry 4.0 and IoT became buzzwords, we were already awash in data. Lots of data. The question was soon asked, “What does all this data do for us?” The answer was easy – not much. This led the team to their first realization: Data that doesn’t lead to action is useless!

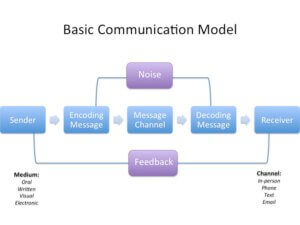

The Communication Model

The Communication Model

What is the difference between data and information? Data is the raw information we get sent every day. Turning it into information involves taking the data, formatting it, interpreting it, deploying it into a series of actionable tasks (jobs) to achieve the end result that customer demands. Understanding this concept is what led our team to realize that ultimately, we were really in the information processing business.

In a perfect world, the classic communication model for a fabrication company works like this: The customer has a need that they encode and send to the fabricator via EDI who decodes the message, communicates it to their shop floor and makes the part. If this process is done correctly, the finished part is delivered on time and is identical to the customer’s request.

However, we don’t live in a perfect world. There are tons of barriers that can cause confusion in the deployment of these signals (change orders, rev changes, and schedule changes to name a few). These “barriers” can distort the original demand line and lead to a series of MIS-steps: Misinterpretation, Misinformation, Misunderstanding and Mistakes.

To be successful, a fabrication company has to overcome this message distortion barrier and produce parts that are identical to the customers’ initial request. Our team realized the magnitude of this task when we went though the manufacturing process and identified over 26 variables (from part number to special packaging instructions) for every customer order!

In a future article, we will provide details on how we tackled the task of eliminating the distortion barrier in our communication model and turned idle data into working information.